Iyo laminating process uye glazing process zvese zviri zvechikamu chekumashure-kudhinda kwepamusoro kupedzisa kugadzirisa kwezvinhu zvakadhindwa. Mabasa eaya maviri akafanana, uye ese ari maviri anogona kuita rimwe basa mukushongedza nekudzivirira pamusoro pechinhu chakadhindwa, asi pane mutsauko pakati pezviviri izvi:

Surface finishing

Kupedzisa kwepamusoro kuita kugadzirisa kwakakodzera pamusoro pechinhu chakadhindwa kuti uvandudze kumira kwechiedza, kudzivirira mvura, kupisa kwekushisa, kupeta kupeta, kusapfeka uye kupikisa kwemakemikari echinhu chakadhindwa; kuwedzera kupenya uye unyanzvi hwechinhu chakadhindwa; uye chengetedza zvakadhindwa. Uye basa rekunakisa zvinhu zvakadhindwa uye kuwedzera kukosha kwezvinhu zvakadhindwa. Nzira dzakajairika dzekugadzirisa pamusoro pezvinhu zvakadhindwa dzinosanganisira glazing, lamination, foiling, kufa-kucheka, creasing kana kumwe kugadzirisa.

01 zvinoreva

Laminationi-post-printing process umo firimu repurasitiki rakaputirwa ne-adhesive rakavharwa pamusoro pechinhu chakadhindwa. Mushure mekupisa nekumanikidza kurapwa, iyo yakadhindwa nyaya uye firimu repurasitiki rinonyatsobatanidzwa kuti rive pepa-plastiki yakabatanidzwa chigadzirwa. Iyo laminating process ndeye yepepa-yepurasitiki inoumbwa maitiro mune inoumbwa maitiro uye yakaoma composite.

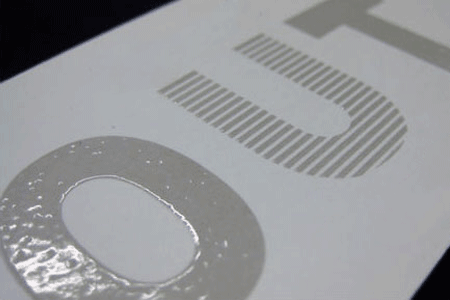

Kupenya inzira iyo pendi isina ruvara inopenya inoiswa (kana kupfapfaidzwa kana kudhindwa) pamusoro pechinhu chakadhindwa. Mushure mekuenzanisa uye kuomeswa (calendering), iyo yakaonda uye inopenya inopenya inoumbwa pamusoro pechinhu chakadhindwa. Iyo nzira ndeyekupfekedza (inowanzozivikanwa seIyo maitiro ekuisa varnish (kusanganisira film-forming resin, solvent uye additives) pamusoro pechinhu chakadhindwa chekuenzanisa nekuomesa.

02 Basa uye zvinoreva

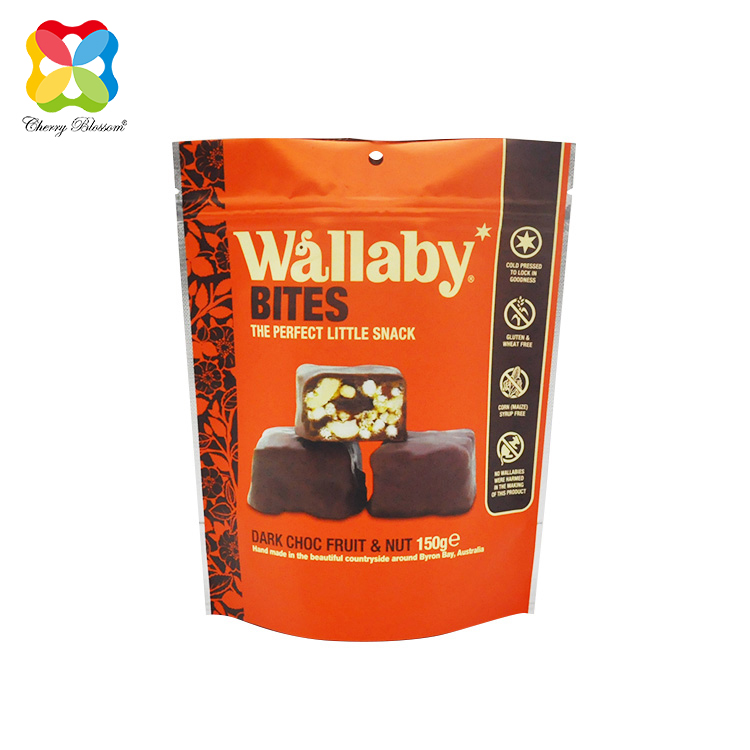

Mushure mekunge pamusoro pechinhu chakadhindwa chakafukidzwa nechidimbu chefirimu repurasitiki (kuputira) kana kuputirwa nependi yependi inopenya (glazing), iyo yakadhindwa inogona kuitwa kuti ive nemabasa ekudzivirira kurwisana, hunyoro-hupupuriro, mvura uye mvura. anti-fouling, nezvimwewo, izvo zvisingangodziviriri zvakadhindwa, asiwo zvinodzivirira zvakadhindwa. Kuwedzera hupenyu hwayo hwesevhisi, inovandudzawo kupenya kwepamusoro pechinhu chakadhindwa, inosimudzira kukosha kwayo kwekushongedza, inoita kuti magirafu akadhindwa uye mavara apenye muruvara, uye ane simba rekuona maitiro, nokudaro achivandudza kunaka kwechigadzirwa uye kuwedzera kuwedzera kukosha. Semuyenzaniso, bhuku butiro lamination, pamusoro glazing of cosmetic packaging mabhokisi, nezvimwewo.

Naizvozvo, laminating uye glazing ndeimwe yeakanyanya kugadzirisa matekinoroji ekupedzisira-kudhinda kumusoro kupedzisa kweakadhindwa. Havagoni "kupenya" chete pamusoro pechinhu chakadhindwa uye kukwezva kutarisa kwevatengi, asiwo kuchengetedza nyaya yakadhindwa uye kuvandudza kushanda kwayo. Iye zvino dzava kushandiswa zvakanyanya. Inokodzera kushongedza kwepamusoro kwemabhuku, nguva, maalbum emifananidzo, zvinyorwa zvakasiyana-siyana, mabhurocha ekushambadzira uye kushongedzwa kwepasi kweakasiyana mapepa ekurongedza zvigadzirwa.

03 Maitiro akasiyana

Firimu yekuputira maitiro Iyo firimu yekuputira maitiro inogona kukamurwa kuita yekuvharisa firimu tekinoroji uye pre-kuputira firimu tekinoroji zvinoenderana neyakasiyana mbishi uye michina inoshandiswa.

1) Thecoating film process first inoshandisa roller coating device kuti ipfekedze zvakaenzana kunamira pamusoro pefirimu repurasitiki. Mushure mekupfuura nemuchina wekuomesa, iyo inonyungudutsa mune inonamira inoputika, uye ipapo iyo yakadhindwa inodhonzwa kune inopisa yekutsikirira lamination mudziyo. Pamushini, iyofirimu repurasitikiuye zvinhu zvakadhindwa zvinotsikirirwa pamwe chete kuti zvipedze kucheneruka uye kudzorera shure, uye zvino zvinochengeterwa kuumba nekutsemura. Iyi nzira ikozvino inowanzoshandiswa muChina. Kubva pakuona kwezvinhu zvakanamatira zvinoshandiswa mufirimu yekuputira, inogona kukamurwa kuva solvent-based adhesive film uye mvura-based adhesive film.

2) Pre-coating film Iyo pre-coating firimu maitiro ndeyevagadziri vane hunyanzvi kuti vatange-kwakawanda uye zvakaenzana kuisa zvinonamira pamafirimu epurasitiki, akaoma, kudzorera kumashure, uye kuaisa muzvigadzirwa zvinotengeswa, uye ipapo makambani ekugadzira anoisa anonamira-isina coating paari. Kutsikirira kunopisa kunoitwa pamichina yekurarisa yemudziyo kuti upedze kugadzirwa kwelaminating yechinhu chakadhindwa. Iyo pre-coating firimu maitiro inorerutsa nzira yekuputira nekuti iyo yekupfekedza haidi inonamira yekudziya uye yekuomesa system, uye iri nyore kwazvo kushanda. Panguva imwecheteyo, hapana kunyunguduka kwesolvent uye hakuna kusvibiswa kwezvakatipoteredza, izvo zvinovandudza nzvimbo yekushanda; zvinonyanya kukosha, iyo Kuitika kwekukoira kwemhando yekutadza senge mabubbles uye delamination kunodziviswa zvachose. Kujeka kwezvigadzirwa zvakavharwa zvakakwirira zvakanyanya. Kana ichienzaniswa neyakajairwa coating process, ine yakakura tarisiro yekushandisa.

1) Solvent-based glazing Solvent-based glazing inoreva kupenya kunoshandisa benzene, esters nedoro sezvinonyungudutsa uye thermoplastic resin seresin inoumba firimu. Munguva yekugadzira glazing, iyo solvent inoputika uye resin inopolymerize kana Cross-linking reaction inoumba firimu. Iyo inoratidzirwa nediki yekushandisa mari uye yakaderera mutengo, asi iyo solvent volatilization uye yakasara pane yakadhindwa nyaya inokonzeresa kusvibiswa kwezvakatipoteredza uye kukuvadza kumuviri wemunhu.

2) Mvura-based glazing Mvura-based glazing inzira inopenya inoshandisa mvura-soluble resin kana marudzi akasiyana-siyana emvura-akaparadzirwa resin semafirimu-kugadzira zvinhu. Mvura-based glazing pendi inoshandisa mvura sechinhu chinonyungudutsa, uye hapana organic solvent volatile matter panguva yekuputira nekuomesa. Chimiro ndechekuti glazing process haina kunhuhwirira, haina kusvibiswa kune zvakatipoteredza, uye haina kukuvadza kumuviri wemunhu. Inoshandiswa zvakanyanya mukurongedza fodya, mushonga, chikafu, zvizorwa uye zvimwe zvinhu.

3) UV glazing UV glazing ndeye ultraviolet mwaranzi yakaoma glazing. Inoshandisa ultraviolet rays kuti irradiate glazing mafuta kuti pakarepo itange photochemical reaction yemafuta anopenya kuti aite kupenya kwakajeka ne network network chimiro pamusoro pechinhu chakadhindwa. Iyo glazing yekurapa maitiro akafanana nekuomeswa kweiyo UV inki. Iyo inoratidzirwa nekupenya kwakanaka, kusimba kwakasimba kwekupisa uye kupfeka kusagadzikana, kuomeswa nekukurumidza, kuchengetedzwa uye kuchengetedzwa kwezvakatipoteredza. Iine tarisiro yakakura yekusimudzira musika. Kufanana nemvura-based glazing, inonyanya kushandiswa mumishonga, chikafu, nezvimwewo. Product packaging mumunda.

Nguva yekutumira: Zvita-13-2023