Stamping yakakosha simbi mhedzisiro yekushongedza nzira. Kunyangwe goridhe uye sirivheri inki kudhinda kune yakafanana simbi luster yekushongedza maitiro nekupisa stamping, zvichiri kudikanwa kuti uwane simba rakasimba rekuona kuburikidza nekupisa stamping process.

Iyo inoenderera innovation yestamping midziyo uye zvinhu zvinotsigira zvakapfumisa mataurirwo mafomu estamping maitiro. Zvino kune marudzi manomwe estamping matekiniki:

01: Zvakajairika flat stamping

The most commonkupisa stamping ndiko kusiya pasina chinhu kumativi ose kuti uratidzekupisa stamping muviri. Kuenzaniswa nekumwe kupisa stamping, maitiro ekugadzira ari nyore. Kana iyo yakawanda isiri yakakura, zinc ndiro inogona kushandiswa kupisa stamping.Flatstamping zvinoreva kuti ndege yedatum ifa rakati sandara, iro rinodhindwa pabasa rakati sandarara chidimbu kana chikamu chebasa chidimbu.

Rudzi urwu rwekufungidzira runogona kuve rwakanamirwa magiraidhi uye zvinyorwa, izvo zvinogona kupisa zvakadhindwa mundege; Inogonawo kuva flat silicone plate, iyo inopisa yakadhindwa pamufananidzo wakasimudzwa uye zvinyorwa.

02: Munda anti-white stamping

Kusiyana neflatstamping nzira, chikamu chezvidzidzo chinosiiwa chisina chinhu, nepo chikamu chekumashure chirikupisa stamping. Saizi yekupisa stamping nzvimbo inoenderana nezvinodiwa zvekugadzirwa kwechigadzirwa. Kana iyokupisa stamping nzvimbo yakakura, zvinodikanwa kuti utarise kana kuita kwayo kwekunamatira kunosangana nezvinodiwa maitiro.

03: Seta zvitambi

Zvinoenderana nezvinodiwa nemifananidzo, kuitira kuti chidhindo uye kudhinda chikamu chekusanganisa kwakangwara, kudhinda mukudhinda kutanga. Muchigadzirwa chekugadzira, kurongeka kwakakwirira, uye kurongeka kwacho kwakarurama kuti uwane mhedzisiro yakakwana.

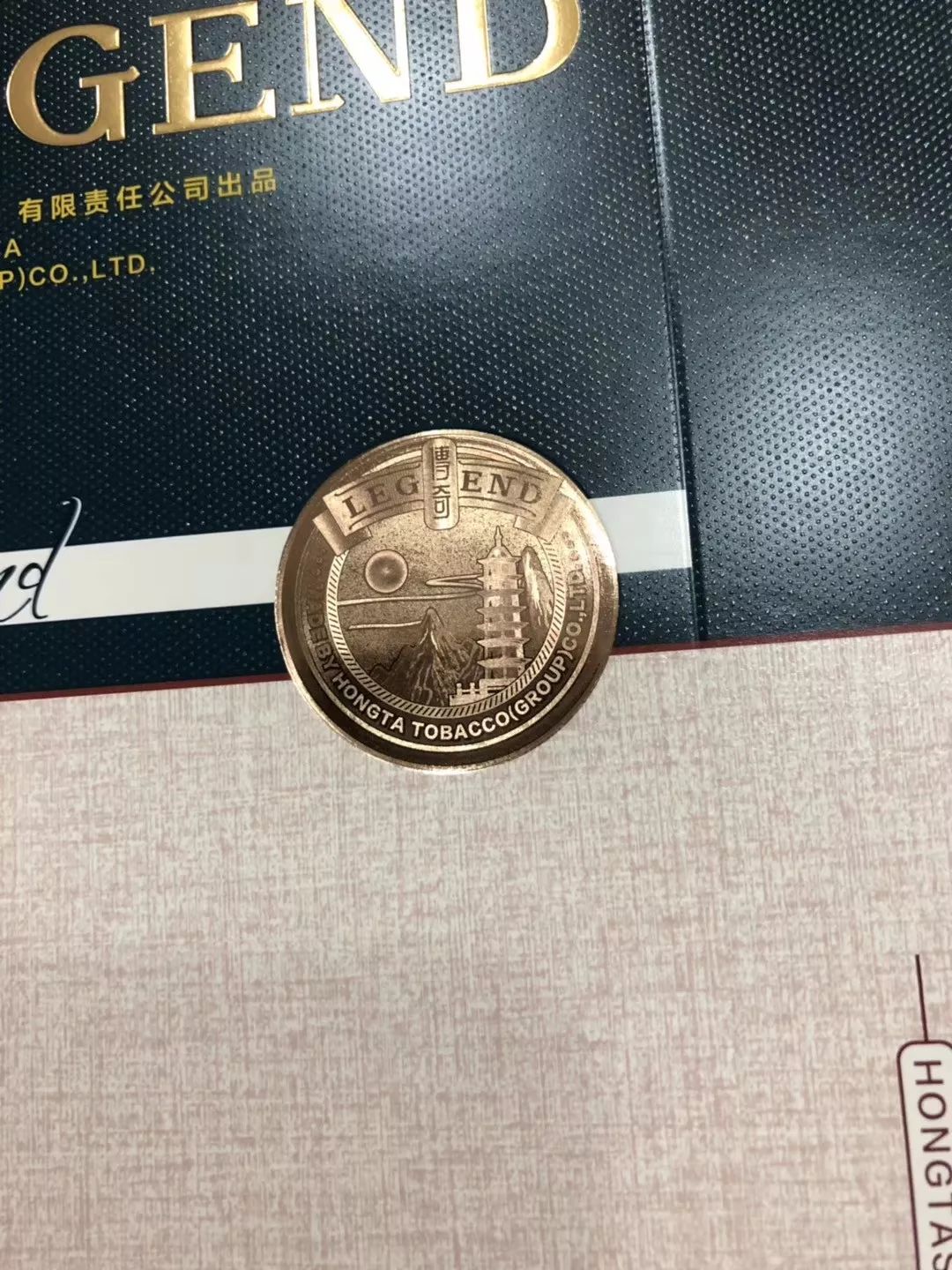

04: Refraction stamping

Panguva yekugadzirwa kwestamping ndiro, mufananidzo mukuru uye magirafu ekumashure anopatsanurwa nemitsara yeukobvu hwakasiyana kana gwara kuumba refraction mhedzisiro uye kusimbisa pfungwa yehunyanzvi yemitsara yemifananidzo. Kazhinji, laser engraving plate inoshandiswa.

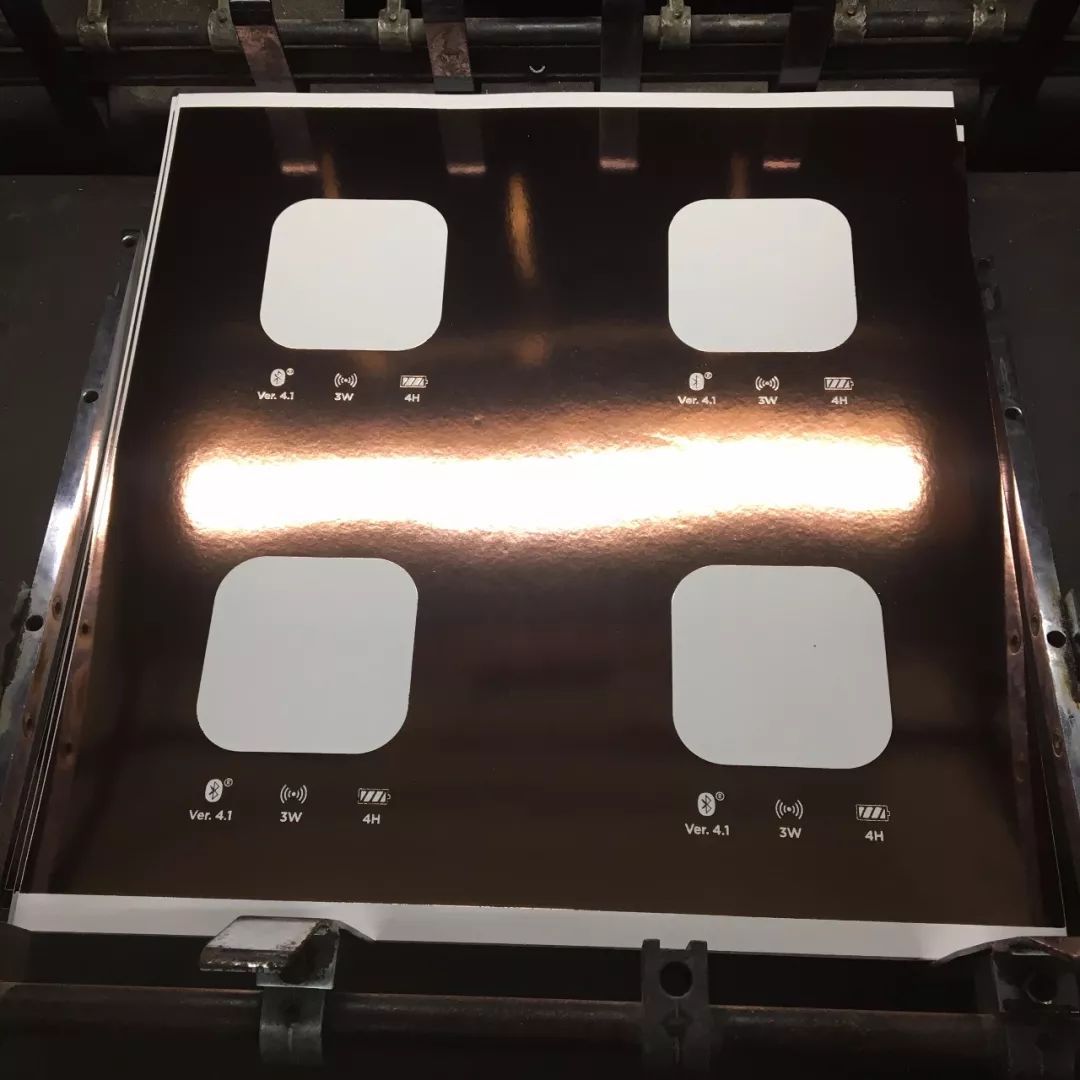

05: Kudhinda kwakawanda

Dzokororwakupisa stamping kwekanopfuura kaviri munzvimbo imwechete yegraphic inoda akawanda process process. Panguva imwecheteyo, kutarisisa kunofanirwa kubhadharwa kune kuenderana kwemapepa maviri egoridhe kudzivirira chiitiko chekusununguka kunamatira.

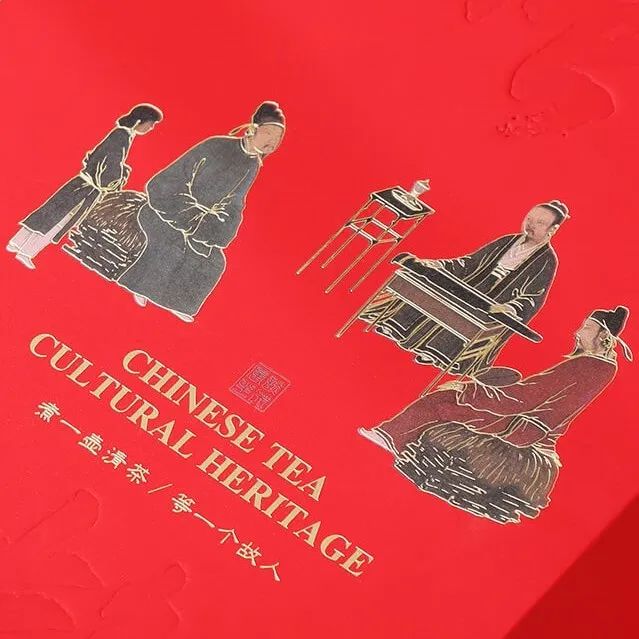

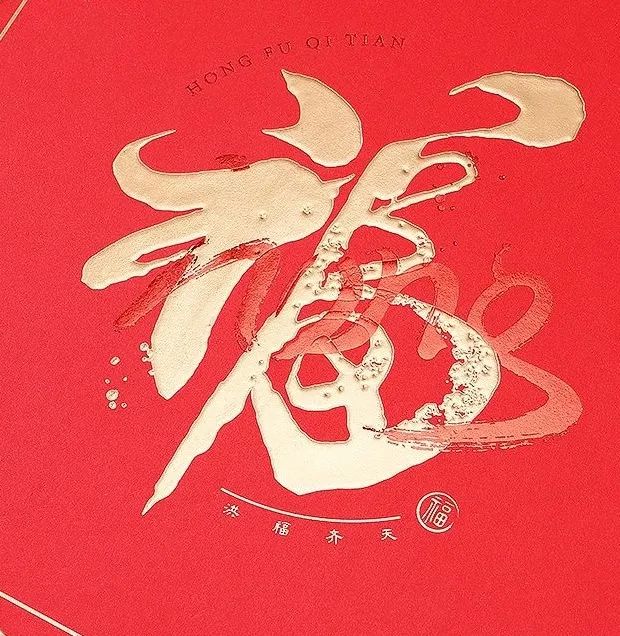

06: Embossed stamping

Izvo zvakafanana nekushongedza uye kudhirowa, asi embossing uye embossing inobhadhara zvakanyanya kunaka kweiyo embossing pane iyo embossing maitiro. Kazhinji, embossing uye embossing mahwendefa anoshandiswa, uye embossing kureba kunofanirwa kunge kuri mukati meiyo tension yepasi peiyo goridhe foil.

Zvigadzirwa zvinogadziriswa ne embossingstamping tekinoroji iripo yakamisikidzwa matatu-dimensional pateni maitiro, saka maitiro ekudhinda karestamping inogamuchirwa. Panguva imwecheteyo, nekuda kwehupamhi hwepamusoro uye zvinodiwa zvemhando yepamusoro, inonyanya kukodzera kushandisainopisastamping tekinoroji.

Sezvaunogona kufungidzira, vagadziri vanofanira kunyatsofungisisa maitiro, uremu, foil yegoridhe uyekudhindainki kana uchisarudza bepa kana zvimwe zvinhu zvinotakura zvematatu-dimensional stamping process. Iko kurongeka kwemberi uye kumashure mativi kwakakosha zvakare.

Panguva imwecheteyo, kukora kwepepa kunogadzirisa kunaka uye mhedzisiro yechigadzirwa chakapedzwa panguva yekushanda. Semuenzaniso, bepa rakanyanya kutetepa kana kuti risina kusimba rinokonzera kuputika kwepepa.

07: Yakakosha maitiro mameseji stamping

Zvinoenderana nezvinodiwa zvekusika, yakakosha maitiro patenistamping inogadzirwa kuratidza akasiyana akakosha maitiro ekuita.

Mukushanda kwekushandisa kwekupisa stamping nzira, kusarudzwa kwesimbistamping ndiro,kupisa stamping bepa, bepa uyestamping kutaura kunobata zvakananga pekupedzisirastamping effect.

Kudhinda iko zvino kwava kushandiswa zvakanyanya munzvimbo dzakasiyana siyana dzekudhinda nekurongedza. Ndiyo chete tekinoroji yekudhinda inogona kuburitsa yakajeka, isina-discolored simbi mhedzisiro pabepa, mapurasitiki, makadhibhokisi uye mamwe madhinda.

Nguva yekutumira: Feb-07-2023